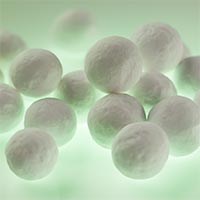

Tabular aluminas are fully shrunk coarse crystalline alpha aluminas that have been converted to their corundum form. Tabular alumina is produced by sintering ball-formed, intermediately burned calcined alumina at a temperature just under the 2040º C melting point of aluminum oxide. These tabular alumina balls are then crushed, graded or screened, ground and blended to a wide range of granular or powdered particle size distributions. AluChem’s (AC99) tabular alumina is available as low or ultra-low soda, de-ironed and de-dusted and in a wide variety of packages.

The typical properties of tabular alumina are:

• Chemical inertness – resistant to most alkalis and mineral acids

• High-density

• Low water absorption

• Extreme hardness

• High thermal conductivity

• Good resistance to thermal and mechanical shock

• High heat capacity

• High electrical resistance

• Excellent abrasion resistance

Tabular Aluminas

Tabular Aluminas Manufacturers

Tabular Alumina suppliers

Tabular Alumina

Tabular Alumina Properties

Reactive grade Tabular Aluminas